What kind of production can bring higher efficiency and lower cost

About LOSUN production line

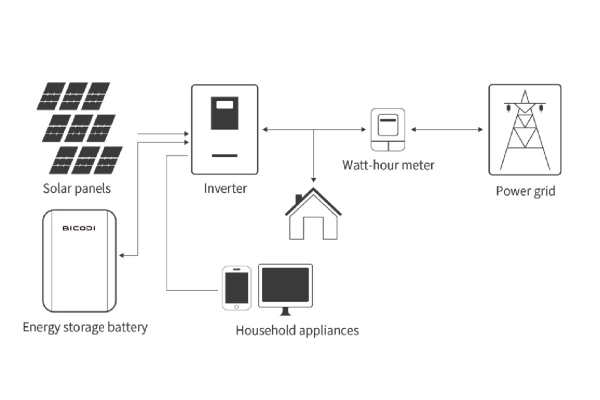

As society's consciousness regarding environmental preservation continues to soar and technological progress marches forward unabated, LOSUN finds itself at the forefront of innovation with its new energy lithium battery module production line. This technological marvel has undergone a gradual maturation process, yielding not only higher efficiency but also a significant reduction in costs for the entire group.

The hallmark of this advancement lies in LOSUN's steadfast commitment to integrating cutting-edge technology and equipment. These state-of-the-art components boast an array of remarkable features, including heightened production efficiency, remarkably low energy consumption, and unparalleled operational stability. Through meticulous engineering and rigorous testing, LOSUN ensures that its production line stands as a paragon of reliability and performance excellence.

Furthermore, the adaptability of LOSUN's technology is a testament to its versatility and forward-thinking approach. By offering customizable solutions tailored to meet diverse requirements, LOSUN caters to a wide spectrum of applications across various industries and sectors. Whether it's for industrial-scale operations or residential energy storage systems, LOSUN's personalized approach ensures that each client's unique needs are met with precision and efficacy.

In the competitive marketplace, LOSUN emerges as a beacon of innovation and reliability, setting new standards for excellence in sustainable energy solutions. Its reputation as a sought-after product is not merely a result of its technological prowess but also a reflection of its unwavering dedication to quality and customer satisfaction. As consumer preferences increasingly gravitate towards eco-friendly options, LOSUN stands poised to lead the charge towards a greener, more sustainable future.

Yet, perhaps the most significant impact of LOSUN's advancements lies in its potential to democratize access to high-performance, safe, and cost-effective energy storage solutions. By driving down costs while maintaining uncompromising quality, LOSUN paves the way for widespread adoption of sustainable energy practices. This, in turn, lays the foundation for a future where clean, renewable energy is not just a privilege but a fundamental right accessible to all.

In essence, LOSUN's journey represents a harmonious convergence of environmental stewardship, technological innovation, and societal progress. As it continues to push the boundaries of possibility, LOSUN not only reshapes the landscape of sustainable energy but also redefines the possibilities for a brighter, cleaner, and more equitable world for generations to come.

LOSUN production process

The production process of lithium battery PACKs entails a meticulously orchestrated series of stages to uphold superior quality and reliability:

-

Cell Testing Phase: This pivotal stage involves a meticulous examination of each produced cell, encompassing visual inspection, internal resistance testing, voltage testing, and more. Through rigorous testing protocols, the quality and reliability of each cell are ensured.

-

Cell Quality Assessment: Cells undergo stringent quality checks to align with industry standards. Parameters such as internal resistance and voltage undergo meticulous evaluation, with cells sorted accordingly to maintain consistent performance within each PACK assembly.

-

Cell Assembly Process: Multiple cells are meticulously connected and secured per design specifications, forming a unified battery PACK assembly.

-

Battery Testing Stage: Assembled battery PACKs undergo comprehensive quality assessments, encompassing charge-discharge testing, cycle life testing, temperature testing, and more. These rigorous tests ascertain optimal performance and longevity.

-

Battery Encapsulation: Battery PACKs undergo encapsulation and insulation processes to enhance safety and stability within external casings, guarding against environmental factors and potential hazards.

-

Secondary Testing and Screening: Following encapsulation, battery PACKs undergo secondary testing and screening to validate quality and performance, ensuring adherence to stringent standards.

-

System Integration Phase: Multiple battery PACKs are seamlessly interconnected and integrated as per design specifications, culminating in the assembly of the complete battery system.

In essence, the production process of lithium battery PACKs is characterized by its intricacy and rigorous quality control measures. From initial cell testing to final system integration, each stage is meticulously managed to guarantee unparalleled performance and stability.

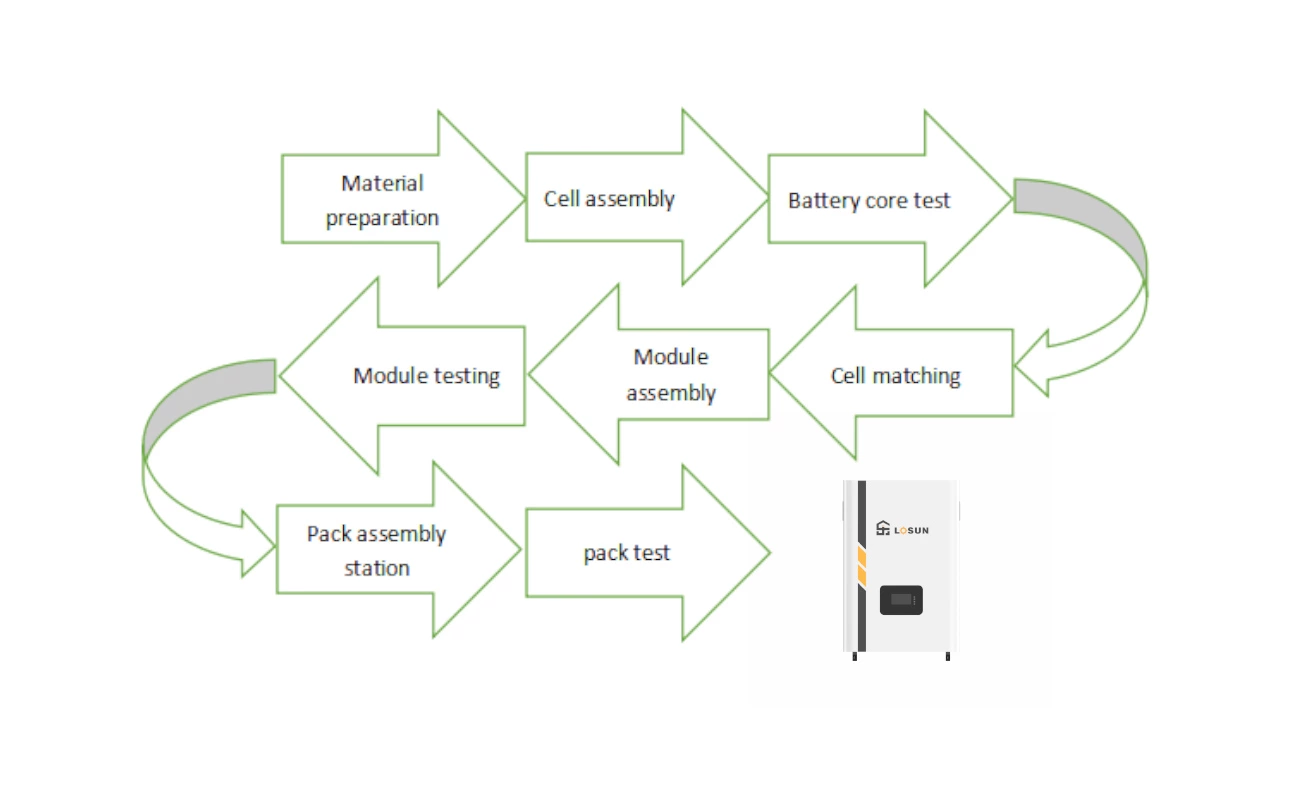

Explanation of the main production stages

-

Material Preparation: This involves receiving, storing, and dispensing materials. Key equipment includes material storage units and weighing devices.

-

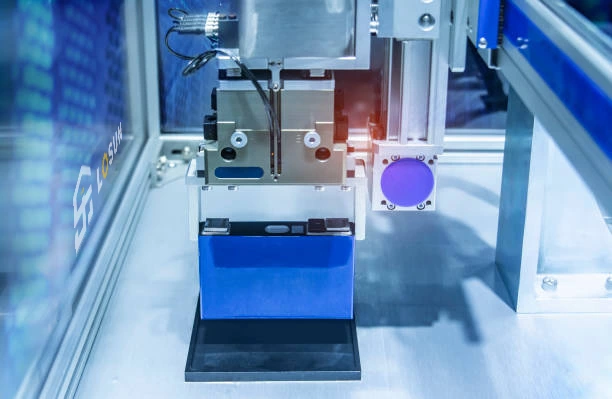

Cell Assembly: Assembling positive and negative electrode sheets with separators to form cells. Equipment includes sheet stacking machines and cell strapping machines.

-

Cell Testing: Testing assembled cells for electrical performance, including voltage, capacity, and internal resistance. Equipment includes cell testing instruments.

-

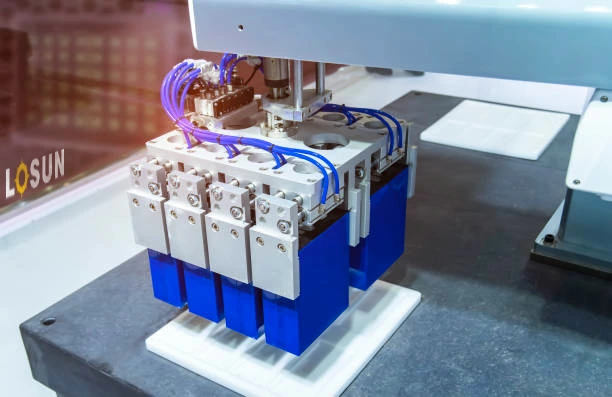

Cell Matching: Classifying and matching cells based on performance criteria. Equipment includes cell sorting devices and matching robots.

-

Module Assembly: Assembling cells with other components such as battery management systems and heat sinks. The battery management system consists of computer control systems, circuit boards, and sensors. Equipment includes module assembly units and laser welding devices.

-

Module Testing: Testing assembled modules for electrical performance and functional validation. Equipment includes module testing instruments and functional testing devices.

-

Pack Assembly: Encapsulating and assembling modules with casings. Equipment includes pack assembly units and sealing devices.

-

Pack Testing: Testing assembled packs for overall electrical performance and safety verification. Equipment includes pack testing instruments and safety testing devices.

In summary, the performance, quality, and safety of batteries are ensured through rational workstation composition, selection of key equipment, and standardized operating procedures. The stability of equipment operation depends on equipment quality, operating techniques, maintenance, and a conducive operating environment. Only through the comprehensive effects of these factors can efficient and stable production of high-quality battery products be achieved.